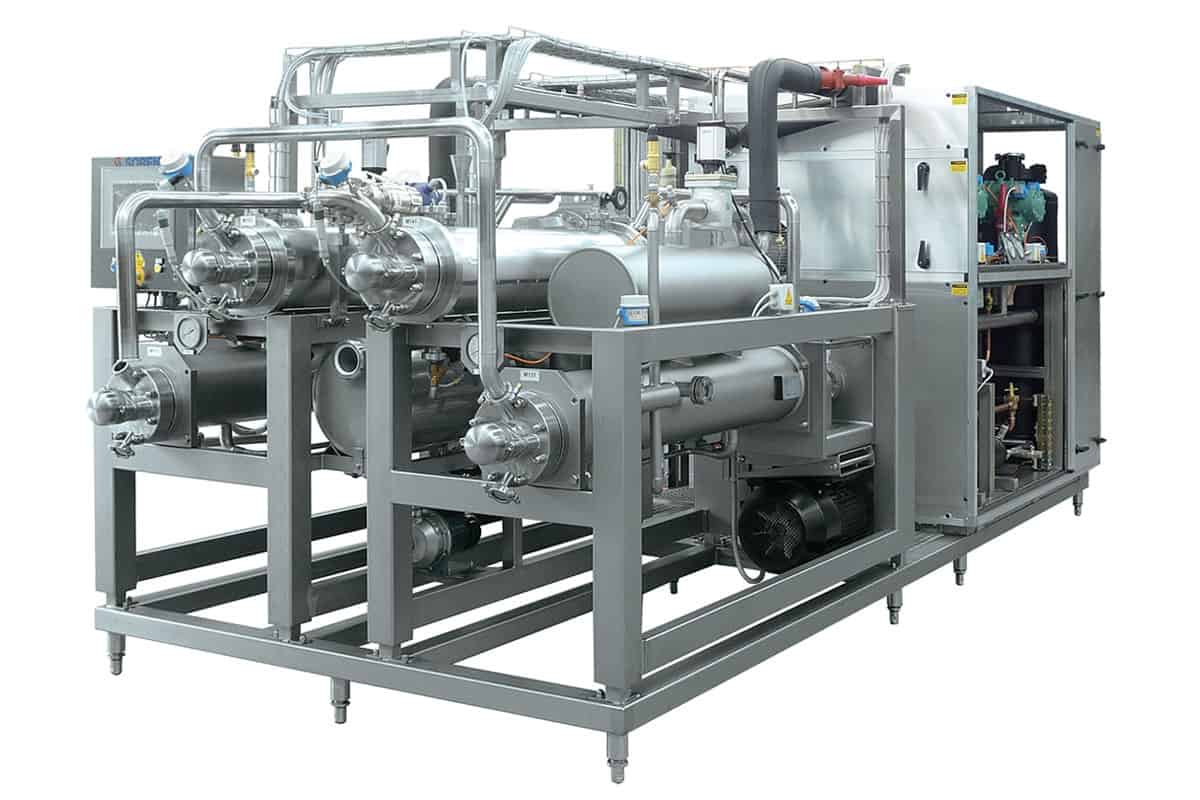

SSHE

Scraped surface heat exchanger

For heating, cooling, crystallizing, pasteurizing, sterilizing.

Suited for:

- High viscosity products (e.g. filling creams, jams, gelatine, processed cheese)

- High difficulty products with large solid particulates (sauces and gravies),

- Crystallization through cooling (margarine, fat and butter),

- Efficient heat transfer through the inhibition of fouling.

Features

- Manufactured with all sanitary/hygienic materials, suited to all processed products and the various CIP procedures.

- HD series can hold up to 30 bar, XHD series up to 80 bar cylinder pressure.

- Stainless steel frame.

- Heat exchange surface from 0,08 to 1,40 m2 per cylinder.

- Suited for all heating/cooling media: Steam, water, brine, glycol, ammonia, freon.

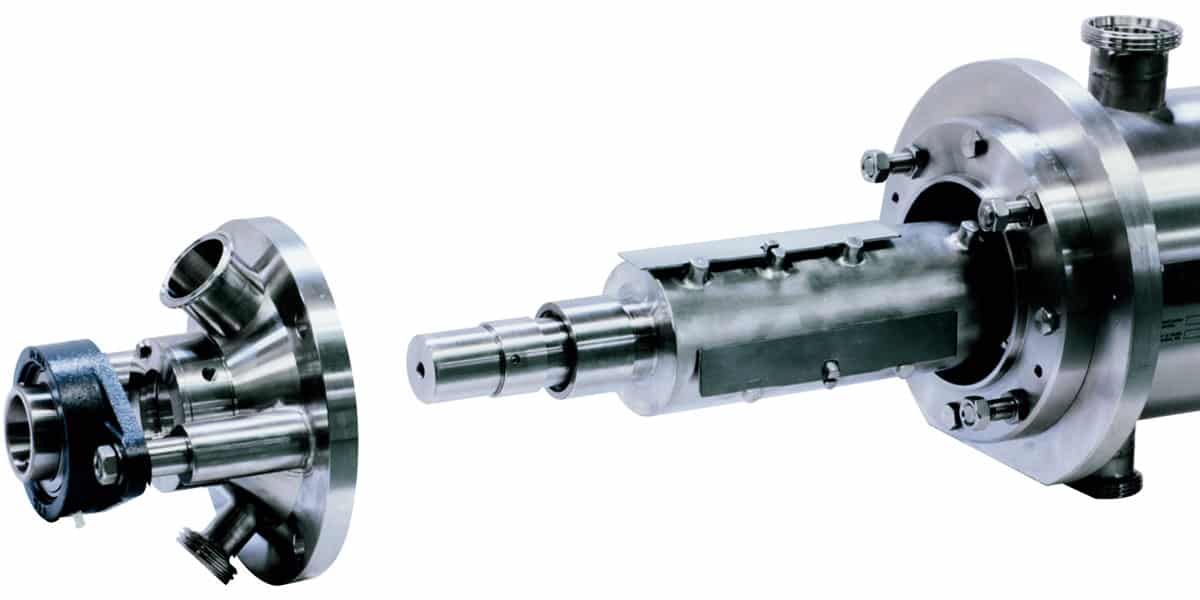

SSHE– model HD and XHD

Water – Brine – Glycol

Cylinders

Standard construction: St. Steel AISI 316L

Options:

- T-inox: St. Steel AISI 420 hardened

- WBC 50: Bimetallic, with high heat transfer coefficient

- Chrome plated nickel: With high heat transfer coefficient

Blades

Standard construction: Plastic: For AISI 316L cylinders

Options: St. Steel AISI 400 series: For the other cylinder

Jacket

St. Steel AISI 304

Dasher

Standard construction: St. Steel AISI 316L – 3 blade rows for HD 100-200, 4 rows for the other sizes

Options: Water circulated dasher to reduce adhesion of product

Dasher drive

Direct coupled gear drive – Belt drive for direct expansion models

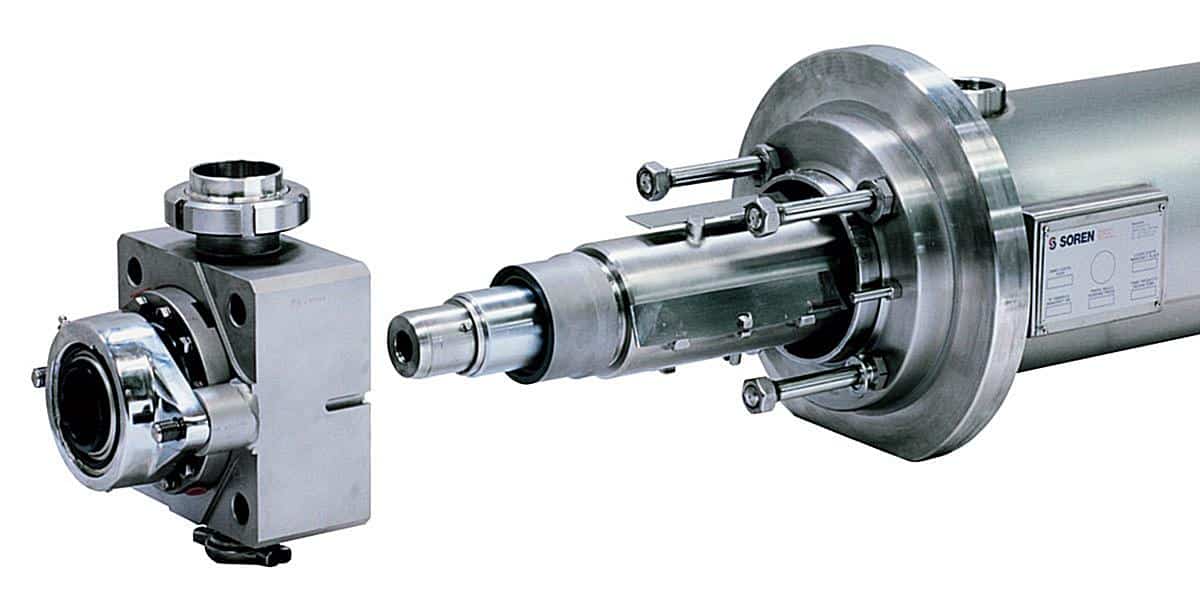

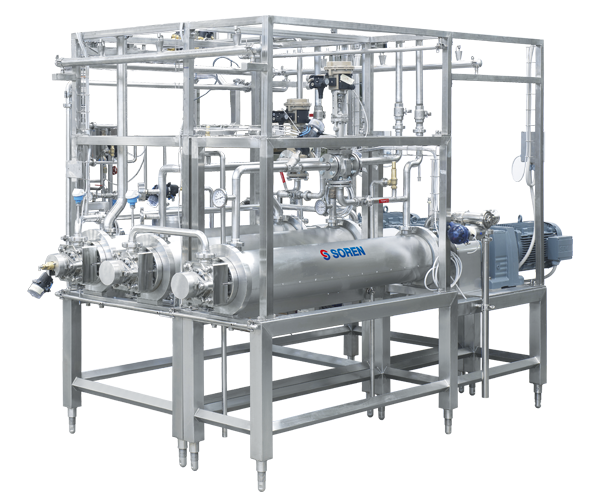

SSHE – model HDE, HDE-M and XHDE

Freon – NH3

In the full flooded direct expansion system, a modulating valve controls the flow of liquid refrigerant from the supply, maintaining the correct liquid level in the evaporation chamber. around the product cylinder. A back pressure valve on the suction side controls the evaporating pressure.

Options: Built in freon refrigeration plant, water or air cooled.

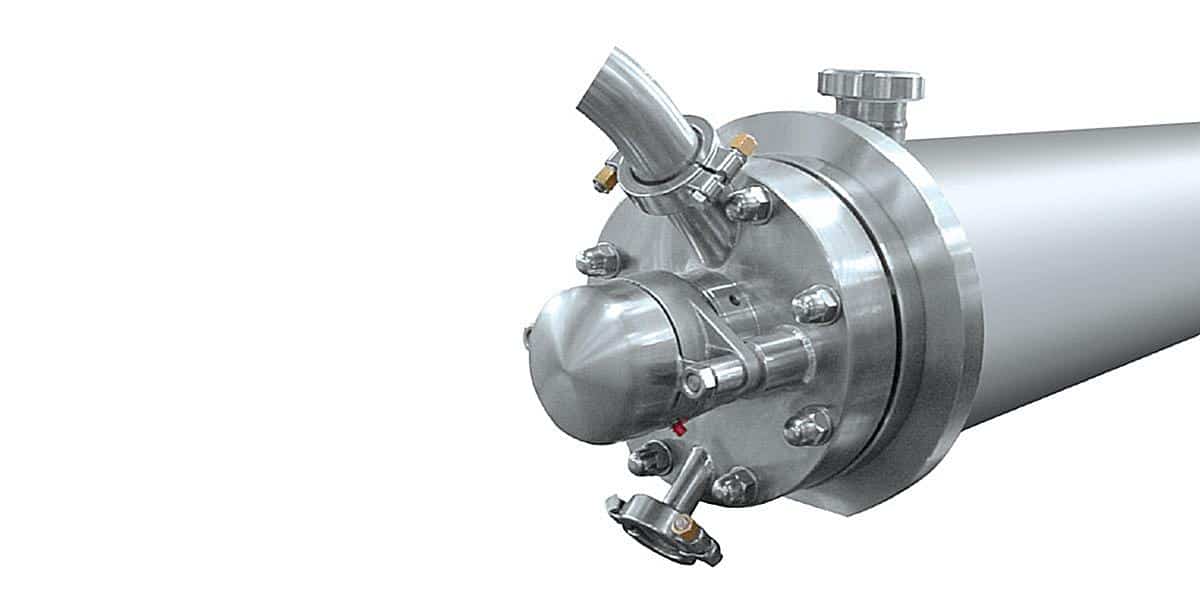

SSHE– model VT

Cylinders

Standard construction: St. Steel AISI 316L

Options: T-inox: St. Steel AISI 420 hardened

Blades

Standard construction: Plastic: For AISI 316L cylinders

Options: St. Steel: For T-inox cylinder

Jacket

St. Steel AISI 304

Dasher

Standard construction: St. Steel AISI 316L

Dasher drive

Direct coupled gear drive

Your products

Per scaldare, raffreddare, cristallizzare, pastorizzare, sterilizzare.

Per il trattamento di prodotti:

• con elevata viscosità (quali creme di farcitura, marmellate, gelatine, formaggi fusi)

• con parti solide incorporate (salse e sughi)

• soggetti a cristallizzazione (margarine, grassi, burro)

• con tendenza a depositarsi sulle superfici di scambio.

Specifiche

• Costruiti con i materiali più adatti ai diversi prodotti e alle diverse procedure di lavaggio.

• Modelli HD fino a 30 bar, XHD fino a 80 bar.

• Struttura completamente inox.

• Superficie di scambio da 0,08 a 1,40 m2 per ogni cilindro.

• Funzionanti con vari fluidi di servizio: vapore, acqua, salamoia, glicole, ammoniaca, freon.

[display-posts post_type=”macchine-e-impianti” taxonomy=”macchine_e_impianti_taxonomy” tax_term=”scambiatori” wrapper_class=”product-list” image_size=”full” order=”ASC” orderby=”title”]