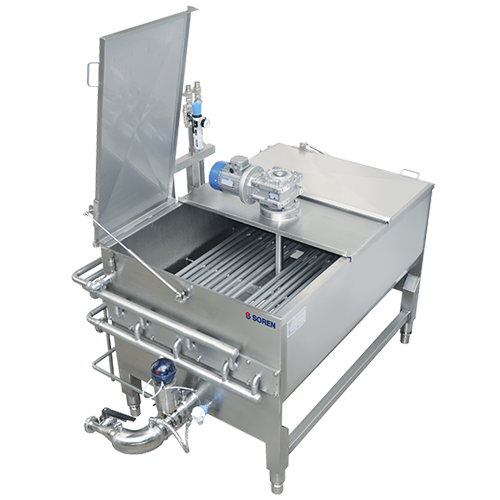

Melters

The Melter

The Melter is a machine designed to melt a wide range of fat based products and/or to blend liposoluble products. It is widely used in many fields: food industry, cosmetic industry, pharmaceutical industry, etc. Our Melter’s flow rates go from 100 to 1500 Kg/h, but it is possible to reach much greater flow rates with custom designs. For an efficient heat exchange we usually use hot water.

The Melter’s active components are:

a. A heating coil for hot water or steam circulation which melts the product.

b. A propeller agitator which keeps the melted product efficiently blended and its composition homogeneous.

c. Spray balls (optional) which guarantee cleansing and rinsing of the machine.

d. A jacket for hot water circulation which keeps the melted products in their liquid phase.

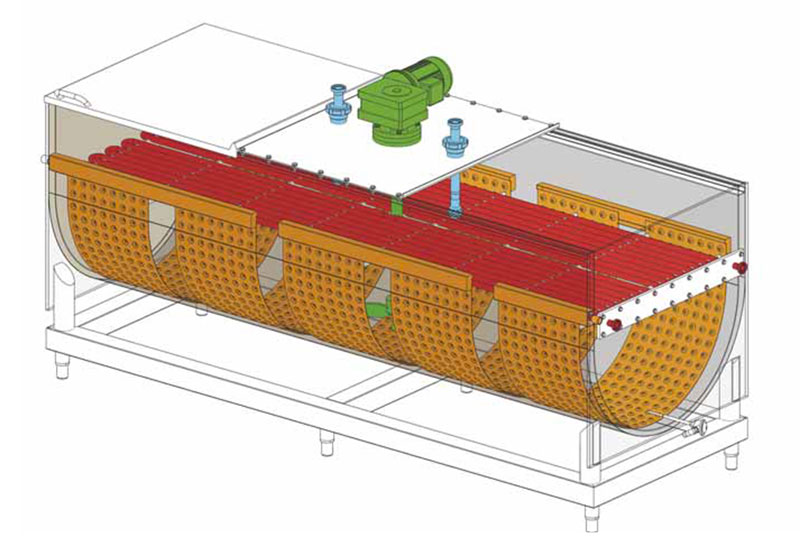

Heat gets usually transferred to the system in the following different ways:

a. -80°C water circulates into the heating coil to melt the product.

b. -50°C water circulates into the melter’s jacket in order to keep the melted products in their liquid phase.

The dimpled jacket for media circulation can withstand higher flow rates with lower pressure drop. Its design provides extremwly efficent heat transfer perfomance; spot welded channels induce the fluid turbulence necessary to obtain high heat transfer coefficients. Media pressure rating to 5 bar.

Specifications for all the Melters

| Product contact surfaces made of AISI 316 St. Steel |

| CIP sprayballs (optional) |

| Heat exchange jacket for circulation of media at 5 bar max pressure |

| Mineral wool insulation, 50 mm thick |

| Outer jacket of AISI 304 St. Steel |

| Satin finished internal surface, 2B external |

| Two product connections on top |

| Agitator with inclined blades |

Your products

Il Fusore è una macchina progettata per fondere e stoccare una grande varietà di grassi. Le portate dei nostri fusori vanno d 100 a 1500 kg/h, ma è possibile arrivare fino a portate molto maggiori con design ad hoc. Per i nostri fusori generalmente si consiglia di utilizzare come fonte di calore acqua calda.

Specifiche per tutti i fusori

Parti a contatto con il prodotto in AISI 316L • Sfere di lavaggio CIP (opzionali) • Intercapedine per acqua/vapore max 5 bar • Finitura interna: satinatura fine, finitura esterna: 2B • Coibentazione in lana minerale 50 mm • Rivestimento esterno in AISI 304 • Scarico di fondo • n.2 connessioni per alimentazioni ingredienti • Agitatore a pale inclinate

I componenti attivi di un Fusore sono:

a. Una serpentina per la circolazione di acqua calda o vapore, al di sopra della quale porre i blocchi di grasso da fondere.

b. Un agitatore a pale per garantire una costante miscelazione e mantenere omogeneo il prodotto fuso.

c. Spray balls per un efficace fase di lavaggio del fusore.

d. Una camicia per la circolazione di acqua calda per mantenere a temperatura i blocchi fusi sul fondo del fusore.

Il calore viene di solito fornito seguendo le seguenti modalità:

a. Acqua a una temperatura di circa 80°C circola nella serpentina con lo scopo di fondere i blocchi di prodotto.

b. Acqua a una temperatura di circa 40°/50°C circola in una camicia che avvolge il fondo bombato del fusore con lo scopo di mantenere allo stato liquido i blocchi precedentemente fusi.

L’intercapedine per la circolazione del fluido di scambio è eseguita mediante l’applicazione sul serbatoio di una lamiera bugnata saldata a punti. Si ottiene in questo modo una doppia parete con eccellente resistenza alla pressione max 5 bar. Essa, alimentata tramite opportuni collettori, ha una configurazione che assicura un elevato coefficente di scambio termico.

[display-posts post_type=”macchine-e-impianti” taxonomy=”macchine_e_impianti_taxonomy” tax_term=”fusori” wrapper_class=”product-list” image_size=”full” order=”ASC” orderby=”title”]