Shortening

STORAGE & AUTOMATIC DOSING OF FATS

Natural oils and fats are multi-component mixtures of triacylglycerols, and their composition determines the physical properties and features of the final product. This is why it is customary to use blends of different fats in order to achieve the required characteristics.

Fats are the main ingredient of shortening, therefore tons of them need to be stored and dosed everyday.

That’s why it is important to have each fat and oil stored in storage tanks with temperature control system to keep the temperature above the melting point and then automatically dosed through flowmeters into the mixing tank.

MIXING TANK & STORAGE TANK

Oils and fats are automatically dosed to the mixing tank through flow meters according to the recipe, where they are mixed vigorously with each other as well as all powder ingredients. Once the mixing process is completed, the blend is transferred to a buffer tank.

CRYSTALLIZATION PROCESS

The mix is now ready to be pumped to the thermal processing section where it will undergo crystallization through shock cooling. Before entering the crystallizator, the product can be injected with nitrogen (or any inert clean dry gas) if needed.

A mass flow meter on the product pipe, and a mass flow meter on the nitrogen injection pipe will guarantee a perfectly controlled specific weight.

The crystallization behavior of lipids has important implications in the industrial processing of food products whose physical characteristics, such as consistency, plasticity and melting sensation in the mouth, depend largely on fat crystals. Process parameters such as cooling rate, composition, residence time and agitation rate directly impact crystallization behavior, so the design of a successful crystallization process depends on choosing process parameters that will produce crystals of the required features.

Crystallization occurs through a sequence of interdependent mechanisms which all contribute to the final outcome, and are each uniquely influenced by the choice of process parameters. Control of crystallization to prevent crystal growth or to achieve the desired crystalline attributes is crucial for obtaining high-quality products with long useful life.

SOREN CRYSTALLIZATORS

Soren’s Crystallizators can work both with Freon (with a built-in refrigeration system) and with NH3 (connected to a remote ammonia refrigeration system).

In the fully flooded direct expansion system, a modulating valve controls the flow of liquid refrigerant from the supply, maintaining the correct liquid level in the evaporation chamber around the cylinder.

A back pressure valve on the suction side controls the evaporating pressure.

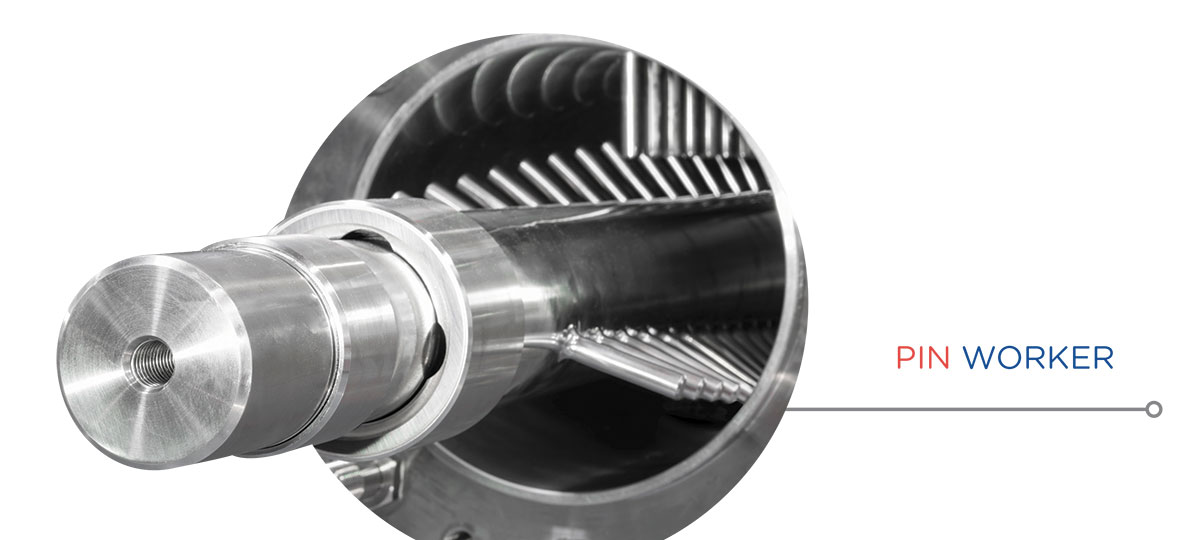

After the crystallization process, the product is kneaded in the Pin Rotor where, by variating the rotation speed and residence time, it is possible to reach the required texture.

The sequence of crystallizators and pin workers may vary according to the capacity of the line and the desired texture.

The sequence of crystallizators and pin workers may vary according to the capacity of the line and the desired texture.

TEMPERING

The product coming out of the crystallizator – pin rotor sequence is transferred to one or more maturation tanks. The product will rest in these tanks for 2-4 hours, during which the crystal structure of the shortening will continue to develop. These tanks have a very steep cone bottom (60°) and are pressured with nitrogen in order to facilitate the discharging of the finished product.

DOSING TO MIXERS

The product can be now dose to all mixers automatically through mass flow-meters and jacketed pipes.

Advantages

- No need for storage rooms and transportation routes inside the factory

- Reduced labor cost by cutting manual operations (loading and unloading of fat blocks, transportation of blocks, unwrapping of blocks,..)

- Cost saving on ingredients (liquid oil instead of processed fat)

- Reduction of mixing time: with a softer and more plastic shortening, the mixing time is reduced by up to 50%

- Higher product repeatability: a softer shortening is easier to spread homogeneously through the product

- Consistent quality of shortening, avoid suppliers variations

- Higher hygienic standards due to reduced manual operations