Pilot Plants

General features

Our pilot plants are designed and built to accurately simulate industrial processes such as preparation, cooking, pasteurization, UHT and cooling, of viscous products, in small scale. These laboratory units give you the possibility to combine high performance industrial processing with the chance to test new products using feeds that go from 15 to 100 kg/h, allowing significant product saving.

They are suited to process a very large range of products:

| Filling creams (aerated and non-aerated) |

| Margarine and plasticized fats |

| Ice cream, pudding and cream mixes |

| Parfaits, mousse and ice creams |

| Jams, gelatins and syrups |

| Sauces |

| Mayonnaise and ketchup |

Standard features

First section: preparation, mixing and heating

– Preparation and mixing tank:

- Capacity: 100 liters

- Parts in contact with product: AISI 316

- Jacket on wall and bottom for hot water circulation

- Anchor agitator with scraper blades

- Impeller housed at the bottom

- Emulsifier

– Rotative pump for product transferring

– Centrifugal pump for closed loop cleansing of the plant (C.I.P.)

– Electrical boiler (cap. 50 l) for hot water production with temperature up to 95°C, with temperature regulation system and circulation pump

– Option: vacuum cooking of sauces in tank:

- Vacuum production system (max vacuum residue: 0,1 bar)

- Vapors suction system

- Vapors condensation system

Second section: Thermal treatments

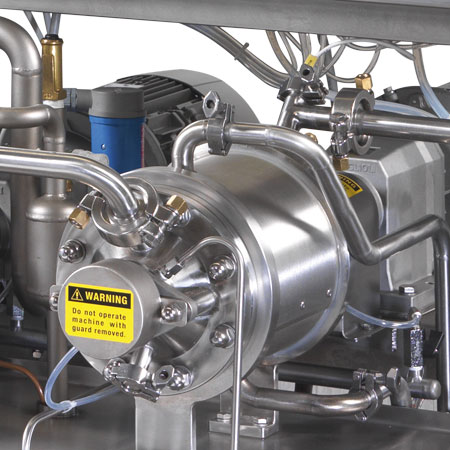

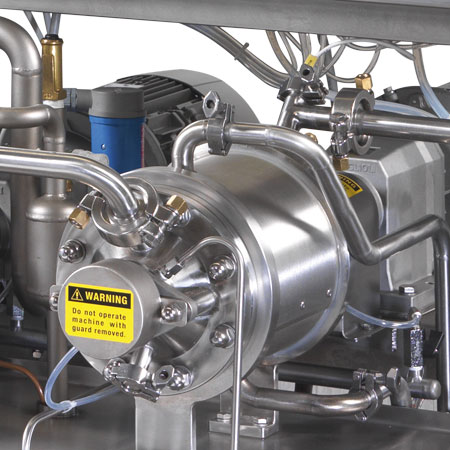

All our scraped surface heat exchangers, mod. HD100, feature:

– Motor with speed controlled by a frequency converter

– Regulation and transmission of the temperature of the exiting product

– Nickel-Chrome or WBC alloy cylinder

– Dasher with 4 rows of INOX blades

The sequence of thermal treatments features:

– 1° SSHE for the pasteurization/sterilization with steam

– Electrical boiler (cap. 50 l) for the production of steam with pressure up to 5 bar (151°C), with temperature and pressure regulation system

– 2° SSHE for cooling with tower water

– 3° and 4° SSHE for final cooling to ~15-20°C with glycol

– Glycol -15°C production unit (cap. 5.000 kcal/h):

- Freon R404A compressor with condensation by water

- Plates evaporator

- Circulation pump

- 50 liters storage tank

- Glycol temperature regulation system

Air or nitrogen injection for aeration of the product

– Compressed air or nitrogen injection system with mass flow meter (cap. 1-60 l/h). The injection valve can be placed at the entrance of any SSHE.

Electrical and power panel

– The electrical and power panel is entirely made of AISI 304 and stores all the required hardware for a correct automation of the plant.

Options

Option 1: Freezer

– Freezer mod. CS100 for the cooling of the product from +15 to -5°C:

- Nickel-Chrome cylinder

- Open or closed type dasher, with 4 rows of INOX blades

- Refrigeration unit with Freon R404 compressor

- Viscosity and temperature automatic control system

Option 2: Pin Worker

Pin worker for fat crystallization, paired with a motor with speed controlled by a frequency converter.

Option 3: Creams storage units with vacuum (0,1 bar)

– Storage tank:

• Capacity: 100 liters

• Parts in contact with product: AISI 316

• Jacket on wall and bottom for hot water circulation

• Anchor agitator with scraper blades

– Rotative pump for product transferring

– Centrifugal pump for closed loop cleansing of the plant (C.I.P.)

– Vacuum production system (max vacuum residue: 0,1 bar)

Option 4: Homogenizer

– Capacity: 20 -100 kg/h

– Maximum operating pressure: 250 bar

– Single stage

– The design of the pistons is chosen accordingly to the product.

Standard features

First section: preparation, mixing and heating

– Preparation and mixing tank:

• Capacity: 100 liters

• Parts in contact with product: AISI 316

• Jacket on wall and bottom for hot water circulation

• Anchor agitator with scraper blades

• Impeller housed at the bottom

• Emulsifier

– Rotative pump for product transferring

– Centrifugal pump for closed loop cleansing of the plant (C.I.P.)

– Electrical boiler (cap. 50 l) for hot water production with temperature up to 95°C, with temperature regulation system and circulation pump

– Option: vacuum cooking of sauces in tank:

• Vacuum production system (max vacuum residue: 0,1 bar)

• Vapors suction system

• Vapors condensation system

Second section: Thermal treatments

All our scraped surface heat exchangers, mod. HD100, feature:

– Motor with speed controlled by a frequency converter

– Regulation and transmission of the temperature of the exiting product

– Nickel-Chrome or WBC alloy cylinder

– Dasher with 4 rows of INOX blades

The sequence of thermal treatments features:

– 1° SSHE for the pasteurization/sterilization with steam

– Electrical boiler (cap. 50 l) for the production of steam with pressure up to 5 bar (151°C), with temperature and pressure regulation system

– 2° SSHE for cooling with tower water

– 3° and 4° SSHE for final cooling to ~15-20°C with glycol

– Glycol -15°C production unit (cap. 5.000 kcal/h):

• Freon R404A compressor with condensation by water

• Plates evaporator

• Circulation pump

• 50 liters storage tank

• Glycol temperature regulation system

Air or nitrogen injection for aeration of the product

– Compressed air or nitrogen injection system with mass flow meter (cap. 1-60 l/h). The injection valve can be placed at the entrance of any SSHE.

Electrical and power panel

– The electrical and power panel is entirely made of AISI 304 and stores all the required hardware for a correct automation of the plant.

OPTIONS

Option 1: Freezer

– Freezer mod. CS100 for the cooling of the product from +15 to -5°C:

• Nickel-Chrome cylinder

• Open or closed type dasher, with 4 rows of INOX blades

• Refrigeration unit with Freon R404 compressor

• Viscosity and temperature automatic control system

Option 2: Pin Worker

Pin worker for fat crystallization, paired with a motor with speed controlled by a frequency converter.

Option 3: Creams storage units with vacuum (0,1 bar)

– Storage tank:

• Capacity: 100 liters

• Parts in contact with product: AISI 316

• Jacket on wall and bottom for hot water circulation

• Anchor agitator with scraper blades

– Rotative pump for product transferring

– Centrifugal pump for closed loop cleansing of the plant (C.I.P.)

– Vacuum production system (max vacuum residue: 0,1 bar)

Option 4: Homogenizer

– Capacity: 20 -100 kg/h

– Maximum operating pressure: 250 bar

– Single stage

– The design of the pistons is chosen accordingly to the product.

GENERAL FEATURES

Our pilot plants are designed and built to accurately simulate industrial processes such as preparation, cooking, pasteurization, UHT and cooling, of viscous products, in small scale. These laboratory units give you the possibility to combine high performance industrial processing with the chance to test new products using feeds that go from 15 to 100 kg/h, allowing significant product saving.

They are suited to process a very large range of products:

- Filling creams (aerated and non-aerated)

- Margarine and plasticized fats

- Ice cream, pudding and cream mixes

- Parfaits, mousse and ice creams

- Jams, gelatins and syrups

- Sauces

- Mayonnaise and ketchup