Sauces & Pestos

The sauce preparation system developed over the years by Soren, is based on the idea that the most important aspect of an industrial process is the repeatability of the product’s qualities.

Ideal for cooking and blending a wide variety of products, such as vegetable soups, meat sauces, fish sauces, caramelized onion, and béchamel.

OUR GOAL

To find the key parameters of cooking sauce so that, once the ideal value for each recipe is found, it can be repeated at each production.

SAUCE COOKING TANKS

The capacity of our cooking tanks is virtually endless, and it commonly goes from 50 lt up to 5.000 lt.

COOKING OF THE SAUCE

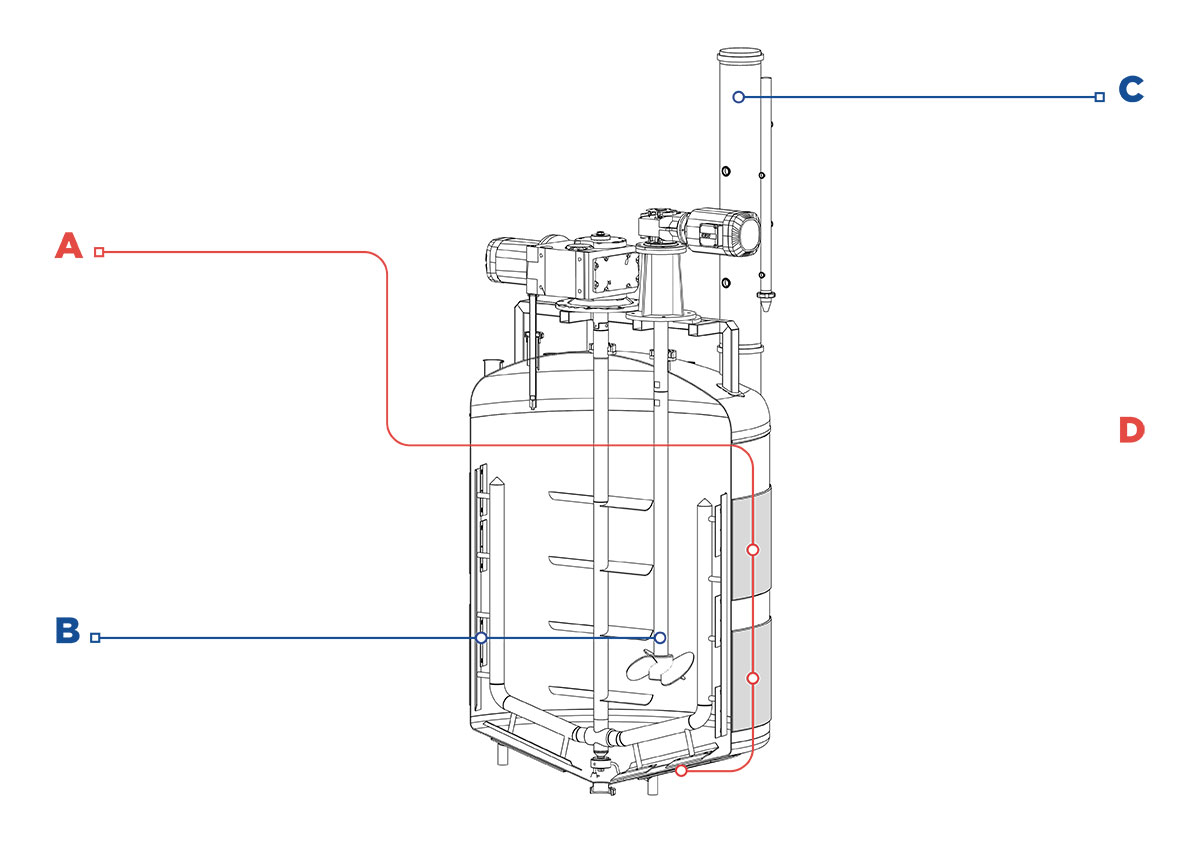

A

Soren’s process tanks have three double jackets: one in the cone bottom and two on the cylindrical section (low and high). These three double jackets are independently usable, allowing their activation only once they are covered with product. This will guarantee the absence of burn-on product on the walls of the tank and thus into the finished product.

B

Since different ingredients require different treatments, Soren’s cooking tanks can be equipped with a wide variety of agitators (cutters, emulsifiers, dissolvers, gentle scrapers, inclined agitators for products in a suspension…)

C

The amount of water that evaporates from a sauce is what makes it “ready”. The conveyance of the vapors to a plate heat exchanger, their condensation and subsequent continuous weighing, allow a constant control to be maintained on the progress of the cooking process. Once the quantity of water that needs to evaporate for the product is known, then the process can be repeated with very high precision at each preparation.

D

Depending on the ingredients that are included in the recipe, the sauce may have to cook at high or low temperature, thus the tank may have to work under pressure or under vacuum.

WE KNOW HOW TO MAKE THE REAL ITALIAN PESTO

Pesto, by definition, is a mix of pounded, shredded ingredients in oil. Generally they are gently mixed at temperatures just above room ones, not cooked like sauces.

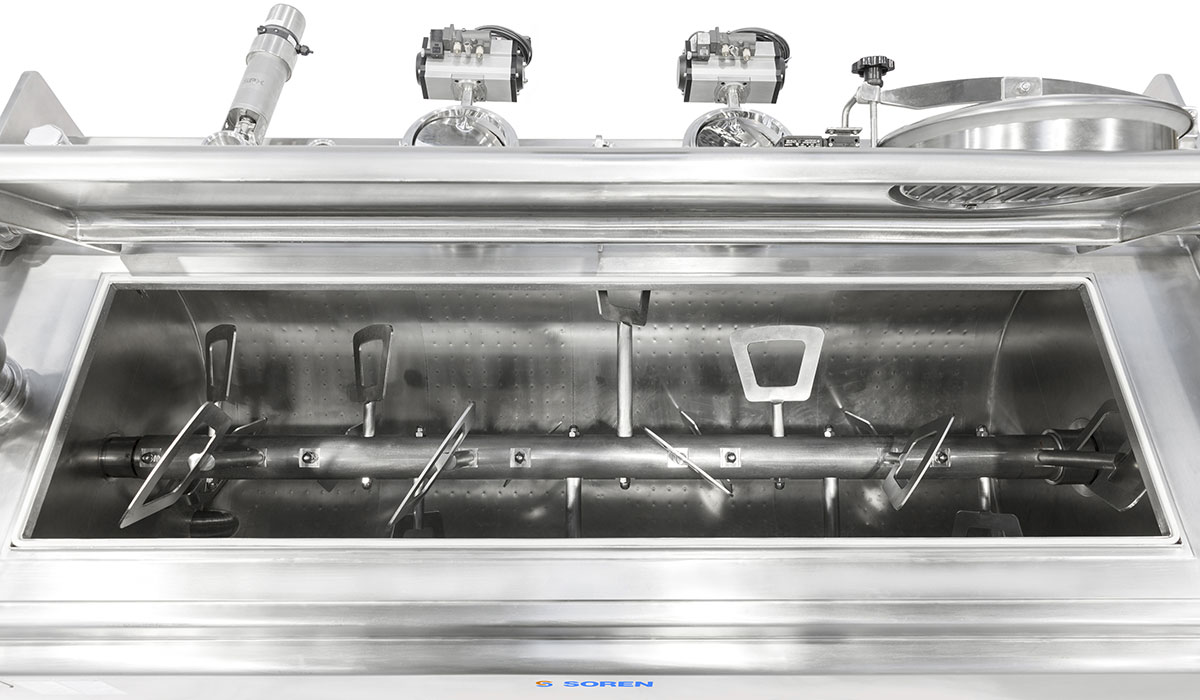

HM PROCESS TANK

Specifically designed to mix high viscosity products.

Pesto differs from sauces in terms of:

- QUANTITY OF SOLID INGREDIENTS PRESENT IN THE RECIPE

- COOKING PROCEDURE

MIXING OF INGREDIENTS

Due to the higher content of solid ingredients, pestos require an horizontal agitation system rather than a vertical one. This is why Soren uses its HM tanks, which is equipped with a double jacket for service fluids and different kinds of agitators.

HORIZONTAL AGITATION SYSTEM

FROZEN READY MEALS

In case of frozen ready meals (IQF products), after going through the aforementioned preparation process, the sauce is pumped to a pre-freezing system. This system consists of Scraped Surface Heat Exchangers (SSHE) that can work with most refrigeration media such as Freon, Ammonia or Glycol.

SHAPING AND FREEZING

The result of the pre-freezing system can now be processed through a volumetric piston depositor or a cutting system, in order to achieve its final shape before going through a freezing tunnel.

FREON OR AMMONIA FREEZER

AUTOMATION

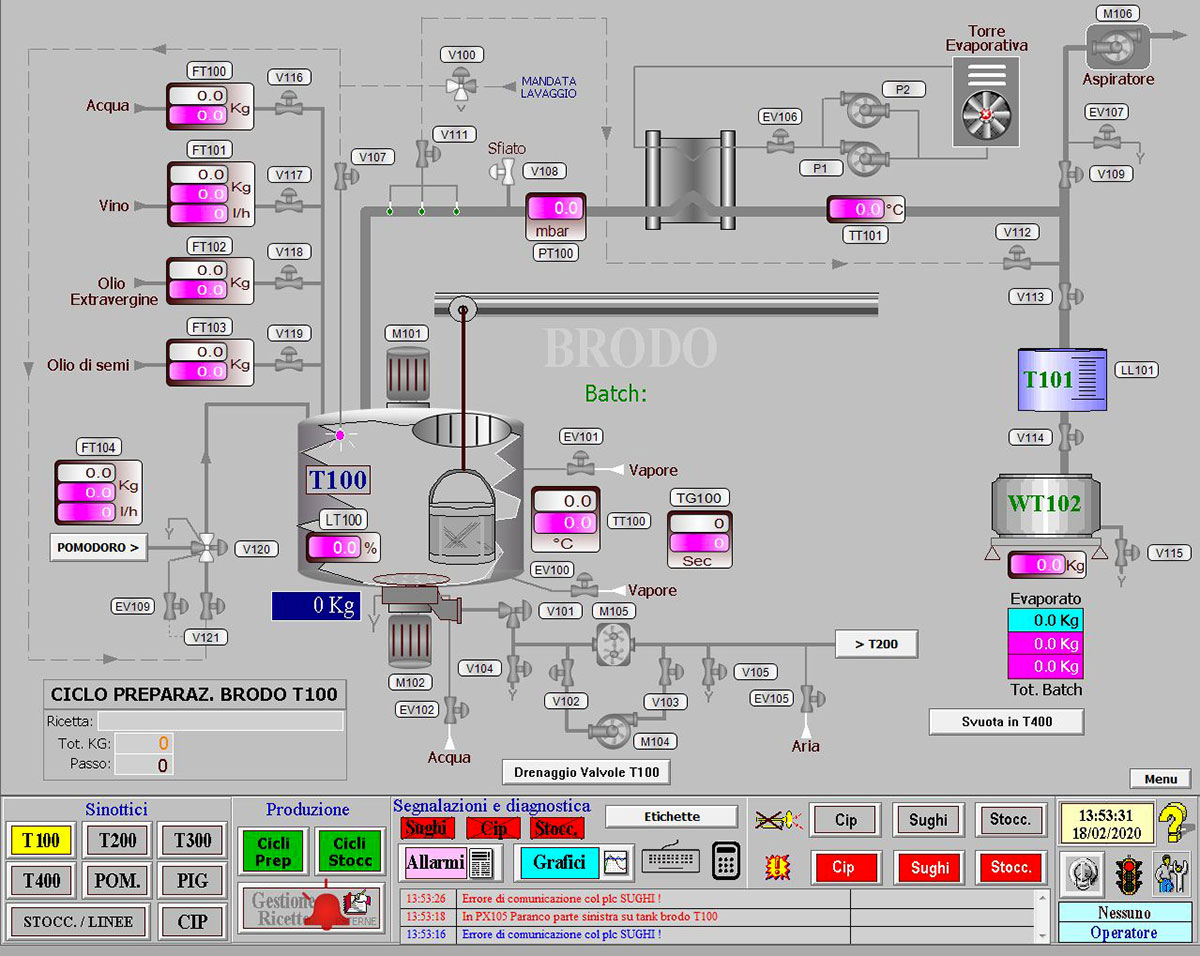

PARAMETERS SETTING & CONTROL

Automation is of key importance when it comes to industrial processes. This is why Soren internally develops the software involved in the running of an automatic system. The operating system is very user friendly and intuitive, with a graphic representation of the process that will allow all users to follow all the variables during the process and, if needed, to modify them. The software also contains all recipes and cooking sequences so that they can be run automatically with only one touch without the possibility of human mistakes.

All modifications to the process can be password protected, so that only a few selected trained operators can have access to them. With the automatic dosing of the ingredients and the automatic handling of the cooking process, perfect repetition of the product quality is guaranteed.

Our automation system allows customers to control all key parameters of the process, such as:

- RECIPE

- COOKING PROCEDURE

- TEMPERATURE

- LEVEL

- FLOW

- PRESSURE

RECORDS TRACKING

The system allows customers to store and keep track of all required parameters.

REMOTE ASSISTANCE

Soren is able, if allowed, to connect remotely to any software at any time in any country. This allows customers to receive instant assistance in case of emergency or in case a sudden change in the process or in the recipe is required.

C.I.P. SYSTEM

CLEANING PROCESS

A cleaning cycle consists of:

FIRST RINSE

Removes the majority of the product residual in the pipes after production. This water goes to drain after going through the plant.

CLEANING WITH ALKALINE DETERGENT OR SODA

This solution can be reused more than once, and it is recycled back to the soda/detergent tank. In this tank, the optimal concentration of soda/detergent is automatically kept through a conductivity meter and a subsequent adjustment of the concentration trough a membrane pump that transfers the soda/detergent from the IBC container directly into the tank.

NEUTRALIZATION WITH ACID SOLUTION

Optional, depending on the product – same as above.

FINAL RINSE WITH FRESH WATER

This water cycle is necessary in order to remove the chemicals that may be left in the pipes from the previous phases. At the end of this phase, the water is still clean as the pipes have already been cleaned. This is why this water is recirculated back to the “first rinse” tank, and will be used as a first rinse water for the following cleaning cycle.

MORE EFFICIENCY

There are different factors that affect the efficiency of the cleaning cycle:

- Temperature of the cleaning solution

- Concentration of the detergent

- Contact time

- Turbulence of the flow

All these parameters can be set and controlled with SOREN automatic CIP system, to guarantee the same cleaning effectiveness at every cycle.

Soren’s C.I.P. System is an investment which pays of itself quickly, by reducing operational costs and by improving the quality and safety of products.

- Recycling

of waste water - Recycling

of detergent solution

- Faster cleaning cycle

= more production time

- Longer life-time

of process plants

- Longer shelf-life

of products

- No human mistake