Margarine

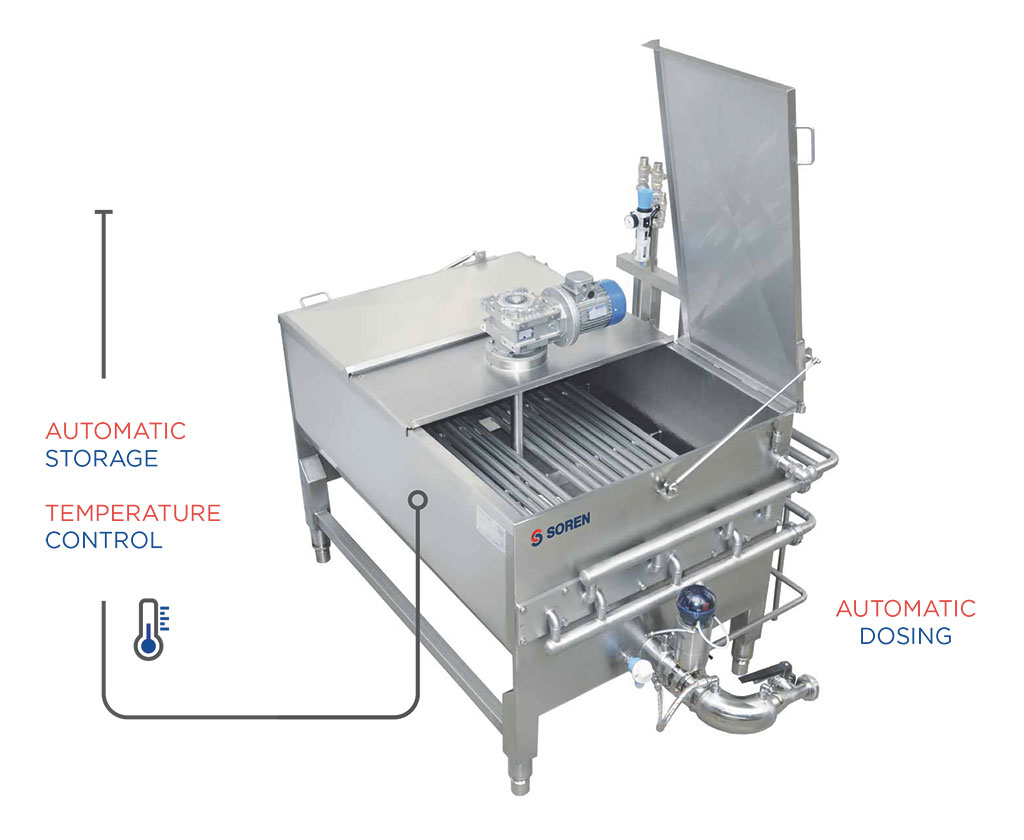

STORAGE & AUTOMATIC DOSING OF FATS

Natural oils and fats are multi-component mixtures of triacylglycerols, and their composition determines the physical properties and the features of the final product. This is why it is customary to use blends of different fats in order to achieve the required characteristics. Fats are the main ingredient (85-65 %) of margarine, therefore tons need to be stored and dosed everyday. That’s why it is important to have an automatic storage and dosing system.

Each fat and oil is melted and stored in storage tanks with temperature control system to keep the temperature above the melting point and then automatically dosed through flowmeters into the mixing tank.

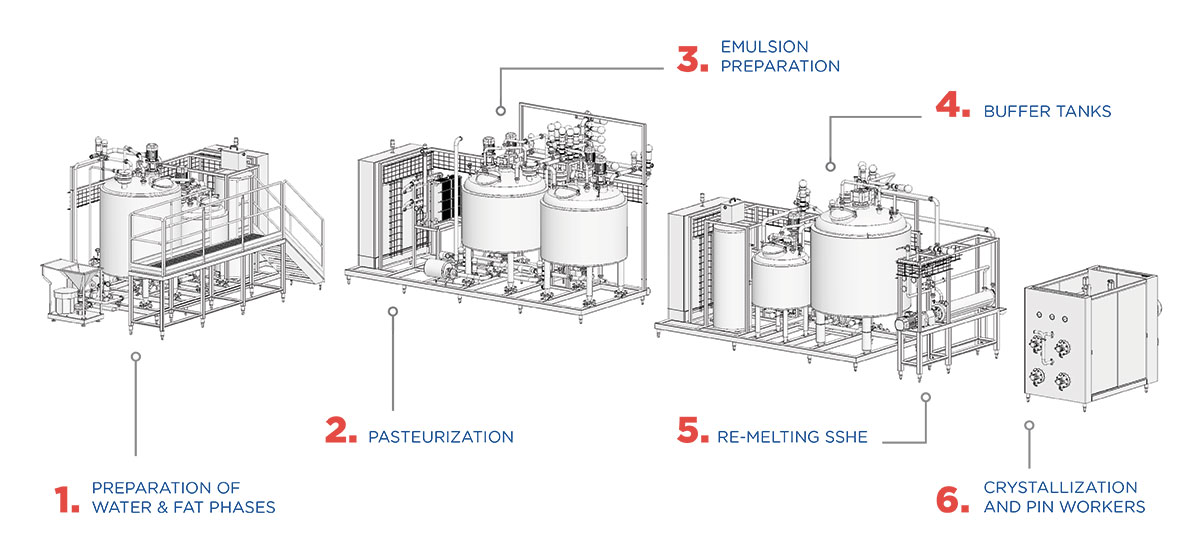

PREPARATION OF WATER & FAT PHASES

The fat phase and the water phase must be prepared separately to make sure that all powder ingredients are properly dissolved.

EMULSION PREPARATION

The fat phase and the water phase are dosed in the mixing tank, our model PC15 + EVF.

A combination of strong mechanical force (electroemulsifier, 1450 rpm) and chemical bounds (emulsifiers), allows the formation of a very stable emulsion, with water droplets of about 3 micron dispersed in the oil phase.

THERMAL PROCESS

1. PASTEURIZATION

Pasteurization is necessary to have a product free from microorganisms by eliminating pathogenic or harmful non-spore-forming ones.

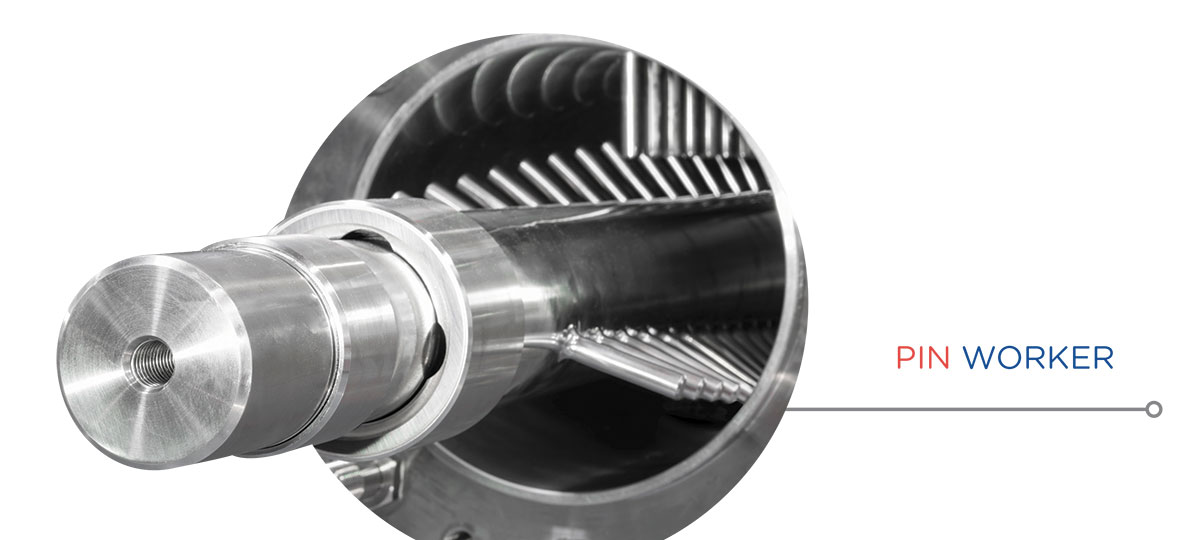

2. CRYSTALLIZATION

The crystallization behavior of lipids has important implications in the industrial processing of food products whose physical characteristics, such as consistency, plasticity and melting sensation in the mouth, depend largely on fat crystals.

Process parameters such as cooling rate, composition, residence time and agitation rate directly impact crystallization behavior, so the design of a successful crystallization process depends on choosing process parameters that will produce crystals of the required features.

Crystallization occurs through a sequence of interdependent mechanisms which all contribute to the final outcome, and are each uniquely influenced by the choice of process parameters.

The main mechanisms of the crystallization are:

NUCLEATION

In order to obtain the formation of crystals from the liquid state, the emulsion must undergo severe and quick cooling in SSHE.

CRYSTAL GROWTH

Once a crystal nucleus has formed, it begins to grow due to the incorporation of other molecules from the supersaturated liquid surrounding the crystal. The application of fats in food products requires that the average diameter of the crystals is less than 30μm to avoid a sensation of grittiness in the mouth.

POLYMORPH TRANSFORMATION

Long-chain compound such as triglycerides may exist in different crystal forms with different rheological properties. In lipids three specific sub-cell types predominate, referring to the polymorphs α, β’ and β with increasing stability (α → β’ →β). Fat with crystals in the β’ form present greater functionality, because they are softer and provide good aeration and creaminess properties. Palm oil has a high stability in the β’ form so is often used in the fats plastification process.

SOREN CRYSTALLIZATORS

Soren crystallization system reaches a high control of the process parameter and allows flexible combinations of the equipment to meet the optimal operating conditions and guarantee the required crystal form and product texture.

SSHE MODELS

| MODEL | HD/ HDE-M 100 | HD/ HDE-M 200 | HD/ HDE-M 400 | HD/ HDE-M 800 | HD/ HDE-M 1100 | HD/ HDE-M 1500 | XHD 1200 | XHD 1800 | XHD 2000 |

| Cylinder diameter (mm) | 114 | 114 | 165 | 165 | 165 | 165 | 165 | 165 | 215 |

| Cylinder lenght | 250 | 500 | 590 | 980 | 1217 | 1638 | 1188 | 1798 | 2140 |

| Heat exchange surface (m2) | 0,08 | 0,16 | 0,29 | 0,48 | 0,59 | 0,80 | 0,56 | 0,84 | 1,40 |

| Dasher type 45 (Ø mm) | 80 | 80 | 114 | 114 | 114 | 114 | 114 | 114 | 166 |

| Dasher type 55 (Ø mm) | - | - | 138 | 138 | 138 | 138 | 138 | 138 | - |

| Product connections (mm DIN) | 40 | 40 | 50 | 50 | 50 | 50 | 65 | 65 | 73 (3”) |

| Net Weight (kg) | 120 | 180 | 290 | 430 | 490 | 550 | 540 | 620 | 750 |

RE-MELTING

In case the of any stop downstream of the crystallizator, the product is re-melted through a Scraped Surface Heat Exchanger and recirculated to a storage tank.

C.I.P. SYSTEM

CLEANING PROCESS

A cleaning cycle consists of:

FIRST RINSE

Removes the majority of the product residual in the pipes after production. This water goes to drain after going through the plant.

CLEANING WITH ALKALINE DETERGENT OR SODA

This solution can be reused more than once, and it is recycled back to the soda/detergent tank. In this tank, the optimal concentration of soda/detergent is automatically kept through a conductivity meter and a subsequent adjustment of the concentration trough a membrane pump that transfers the soda/detergent from the IBC container directly into the tank.

NEUTRALIZATION WITH ACID SOLUTION

Optional, depending on the product – same as above.

FINAL RINSE WITH FRESH WATER

This water cycle is necessary in order to remove the chemicals that may be left in the pipes from the previous phases. At the end of this phase, the water is still clean as the pipes have already been cleaned. This is why this water is recirculated back to the “first rinse” tank, and will be used as a first rinse water for the following cleaning cycle.

MORE EFFICIENCY

There are different factors that affect the efficiency of the cleaning cycle:

- Temperature of the cleaning solution

- Concentration of the detergent

- Contact time

- Turbulence of the flow

All these parameters can be set and controlled with SOREN automatic CIP system, to guarantee the same cleaning effectiveness at every cycle.

Soren’s C.I.P. System is an investment which pays of itself quickly, by reducing operational costs and by improving the quality and safety of products.

- Recycling of waste water

- Recycling of detergent solution

- Faster cleaning cycle = more production time

- Longer life-time of process plants

- Longer shelf-life of products

- No human mistake